The strength of a stable starts with its panels, and Guerilla Steel’s prefabricated system sets the benchmark for durability, protection, and welfare in Australian conditions. Each component is built from 50 mm RHS Duragal® steel, precision welded under controlled conditions for uniform strength and long-term alignment. It’s structural grade steel, alloy coated to resist corrosion, impact stress, and climate changes.

Finished with form ply kickboards and mesh airflow panels, every bay balances protection with ventilation. They don’t warp, rust, or split under pressure like timber or imported kits can. They’re fabricated in Queensland to handle humidity, ammonia, and daily use, delivering decades of reliable performance with minimal maintenance.

Prefab, when done right, isn’t a shortcut; it’s smarter construction: stronger underfoot, safer for horses, and ready to expand the moment you are.

Front Wall – with secure access

Available in 4m & 5m Standard Length

from – $1,050

Side, Rear and Internal Walls

Side / Rear Wall – Ply & Mesh from – $950

Full Ply Wall from – $1,300

Build and Expand Modular

4m × 4m Standard × 2 bays

Base from $8,500

High-quality Australian steel is used in horse stable panels.

Durable Alloy Weld Protection

Duragal isn’t just zinc; it’s an Australian made alloy coating that outlasts standard galvanising by years.

While most imported steel relies on a basic zinc layer, Duragal’s mix of magnesium (3%) and aluminium (2.5%) creates a self-healing barrier that literally repairs and strengthens itself.

Here’s how it compares:

| Coating | Composition | Thickness | Mechanism | Lifespan |

|---|---|---|---|---|

| Z275 (Standard Galvanised) | ~100% Zinc | ≈ 19 µm per side (275 g/m² total) | Sacrificial, zinc corrodes to protect steel | 2–5 years |

| Duragal (Proprietary Alloy) | 94.5% Zinc + 3% Magnesium + 2.5% Aluminium | ≈ 20 µm per side | Self-healing alloy barrier that reforms after scratches/welds | 10–20 years |

When the surface gets nicked or a join exposes fresh metal, Duragal’s alloy reacts and rebuilds its barrier. That’s why it lasts five to ten times longer in humid or ammonia-rich horse stalls.

Horse owners on Queensland’s east coast face heat, salty air, and daily manure exposure. The coating means peace of mind. It’s the reason our ready-built panels stay sound long after ordinary galvanised or painted kits have rusted through.

You’ll see a light “white bloom” appear on the surface in the first year; that’s normal. It’s the zinc alloy doing its job. A quick brushdown and a touch-up once a year keeps that galvanised steel sturdy for decades.

Imported HDPE or thin-tube kits might look clean when new, but UV exposure and flex fatigue soon creep in. Within two or three summers, they start bending permanently; steel simply doesn’t.

Impact Resistance and Structural Behaviour

Think of each panel like a drum.

The 17mm form ply kickboard is the drum skin, strong, dense, and flexible, while the steelwork forms the rim that absorbs and redistributes every strike. Together they turn a sharp kick into dissipated energy, protecting both horse and structure.

Independent equine safety research recommends that stable materials withstand at least 350–400 J of force, equivalent to a 700 kg horse’s full-pressure kick. While formal certification for plywood isn’t published, Australian F11 and F17 rated form ply are designed for heavy duty, load-bearing formwork, a proven indicator of their toughness when backed by rigid steel form. Correctly supported, it provides reliable resistance against repeated strikes without cracking or delamination.

Corrosion & Environmental Resistance

- Alloy-coated Duragal steel resists rust even in ammonia and moisture exposure.

- Prefabricated, sealed joints eliminate water ingress points.

- Gal mesh and form ply combination controls humidity inside the stable while preventing decay or swelling.

Workshop precision vs. field assembly.

Every panel is prefabricated in our Yatala workshop, where welding temperatures, penetration, and alignment are controlled to millimetre accuracy. Consistency is less predictable with field-built configurations assembled on uneven ground.

Square panels, accurate fitment, and zero joint stress are qualities that prevent fatigue over decades of use.

Modular Stable panels: Material Comparison

RHS steel framing eliminates the bending, rotting, and stress degradation seen in timber, while 17 mm structural form ply infills provide the shock and chew resistance required to prevent degradation seen with HDPE.

| Comparison | Benefits | Lifespan |

|---|---|---|

| RHS Steel vs Timber (framework) | RHS steel does not rot, warp, or attract insects. Even treated wood needs repainting and refastening. Timber bends and splits under stress; it keeps full structural integrity. | • Timber 15, 30 yrs (with upkeep) • Steel 50+ yrs (serviceable) |

| HDPE vs Ply (Infill Panels) | HDPE is rot-proof and hygienic but flexes under heavy strain. Good for shock absorption, poor for resilience. 17 mm structural formply delivers rigidity and dimensional stability when supported by a steel frame. | • HDPE 10, 15 yrs under UV/kick stress • Form Ply 15–25+ years |

Service life and total ownership cost

Real value is about how long your investment lasts and how little it costs to maintain. Guerilla Steel’s Duragal alloy coating and fully welded corners deliver a 25+ year service life across inland and coastal Queensland. That’s long after timber or plastic alternatives have failed.

- Timber panels rot, split, or get chewed – 5 to 10 years untreated, maybe 15 if you’re lucky.

- HDPE boards resist rot but crack under UV fatigue, warping within a decade.

- Steel panels are rigid, repairable, and recyclable – still standing long after others are in landfills.

Over 25 years, that means up to 40% lower total cost of ownership compared to timber or HDPE. Minimal repainting, no UV fatigue, and virtually zero replacements – your upfront investment pays back in reliability.

Every detail matters: 17 mm form ply kickboards, 1300 mm internal height, adjustable widths, and slide or swing gates that meet Australian safety standards for horses, cattle, and even sheep.

Optional bamboo infills offer a premium look, while custom panels and breezeway configurations let you tailor the design to your property and livestock.

It’s affordable performance built for the long run, engineered once, customised right, and built to handle the next 25 years of kicks, humidity, and Queensland weather.

Welfare Driven Functional Design: Healthier Horses, Safer Handling

Guerilla Steel’s stable specifications are engineered for your horses welfare – giving horses the air, space, and visibility they need to relax while keeping handlers secure and efficient.

Strength without welfare is a wasteful design. Guerilla Steel panels aren’t only built to stand straight; they’re built to keep horses calmer, handlers safer, and daily routines smoother for years to come. A stable should feel calm the moment you walk in.

Composition of panels and dividers: Designed to enhance airflow and withstand force.

Each Guerilla Steel bay combines solid 17 mm structural formply kickboards below with galvanised mesh airflow panels above, a proven configuration for safety, airflow, and longevity. The solid lower section absorbs impact and prevents cross-kicks, while the open mesh maintains ventilation and natural light throughout the stable line. Every panel stands 2.4–2.5 m high, produced to create a vertical convection channel that draws heat and ammonia upward through the mesh.

In Queensland’s climate, that additional height helps keep the temperature stable several degrees cooler and significantly reduces odour build-up. Cleaner air, dryer bedding, and healthier horses, all within a structure that resists rust, mould, and long-term moisture fatigue.

Design for Visibility and Social comfort.

Horses are social, visual animals, and the mesh upper panels preserve line-of-sight contact between bays to reduce isolation stress without compromising containment. The result is a calmer, more connected, stable setting where horses settle faster and interact more naturally.

Handlers consistently report quieter horses, fewer stressful behaviours like weaving or cribbing, and smoother introductions when new animals arrive, good design shapes temperament as much as training.

NSW DPI recommends tight mesh to avoid injury in Horse Yards. 40–50mm mesh helps prevent hoof entrapment, a small detail but critical for safe containment. Wider 1.5–2 inch gaps risk catching legs or shoes during kicks. Combined with a 50mm steel tube, the result is a stable wall that stays rigid under pressure, protecting both horse and handler.

Management Ergonomics and Low-Risk Handling

Everything about the panel geometry is designed for daily use.

Latch and gate heights align with natural reach to prevent strain; mesh sightlines sit at eye level for quick checks; swing door clearances are sized to move feed, rugs, or gear without fighting the layout.

It’s the sort of detail that saves seconds on every task, and those seconds add up over years of work.

Discipline-Specific Configurations

Because each panel is modular, setups adapt easily to equestrian discipline and horse type:

- Foaling bays: full ply separation for privacy and protection.

- Agistment runs: half mesh splits for social contact without crowding.

- Training lines: open mesh tops for supervision and airflow.

Every variation uses the same design system, so changes or expansions don’t require redesign, just repositioning.

Sustainability: Built for Decades, Not Disposal

Sustainability isn’t just about recycling; it’s about designing infrastructure that earns its keep year after year. Guerilla Steel panels are locally built for longevity, delivering lasting strength, low environmental impact, and full ownership control. Each panel is delivered to perform for decades and still hold value when it’s time to move, upgrade, or sell, a smarter approach that respects both your property and the physical space it stands on.

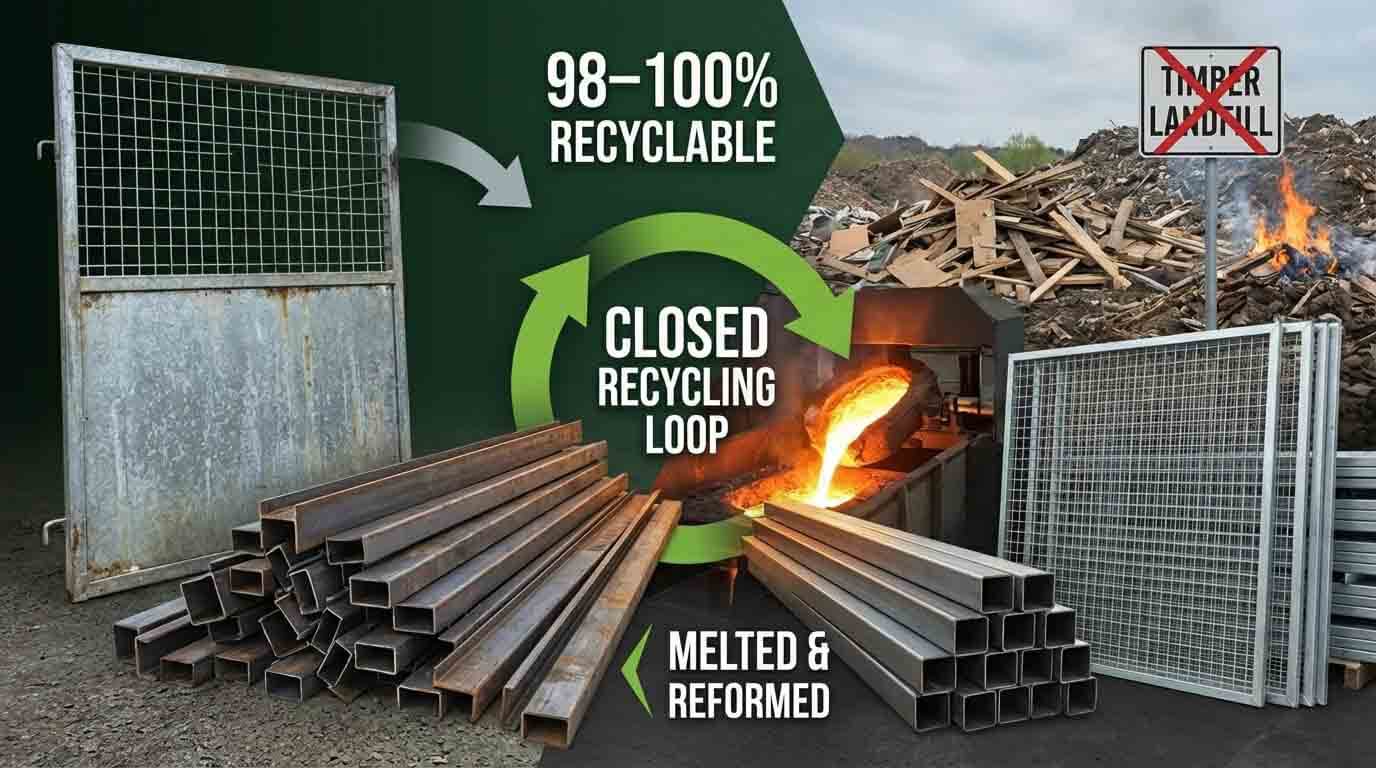

Recyclable, Responsible Materials

Every stable panel – front, rear or side – begins as Australian-made steel, which is 98–100% recyclable indefinitely. Each panel can be repurposed or re-cladded to start its next chapter elsewhere. Nothing was wasted; nothing was left behind.

RHS steel can be melted down and reformed into new steel without losing quality, part of a closed recycling loop where 60–96% of global steel is reused. In Australia, the 2020 National Waste Report suggested 90% of scrap steel recycled. While 20–40% of timber ends up in landfill, its lifespan is often shortened by rot, termites, or fire.

Longevity and Ownership Value

Steel simply lasts longer and delivers 20 or 30 years of structural performance, even in humid or ammonia-rich environments. When kickboards eventually wear, 17 mm ply infills can be replaced without touching the structural form, extending the stable complex’s lifespan indefinitely.

Over decades, this modular longevity means less carbon and fewer rebuilds than timber barns or imported plastic panels.

Local Queensland Fabrication

All Guerilla Steel panels are fabricated in Yatala, QLD. Local manufacturing means lower freight emissions, faster turnarounds, and real accountability. You’re not buying a kit shipped halfway around the world; you’re supporting regional jobs and reducing your carbon footprint at the same time. Every cut, weld, and coat is done by the same hands that design and install it.

Portable Horse Shelter Infrastructure & Environmental Resilience

Prefab isn’t just faster; it’s smarter. Guerilla Steel stables are suitable as movable, long-life assets, ready to adapt when conditions, boundaries, or plans change.

Each structure can be disassembled, transported, and rebuilt within days, keeping full alignment and strength through every move. In scenarios involving floods, bushfires, or relocations, this mobility protects your investment and ensures your infrastructure remains functional wherever you operate.

Across Queensland and Northern NSW, property buyers are catching on. Listings that feature relocatable stables and portable equine housing are rising every year, proof that flexibility now adds real property value.

For landowners on leased blocks, floodplains, or owners with transitional needs, the equation’s simple: invest once, build smart, and let the stable system do the hard work.

Council Rules and Zoning for Portable Stables

While modular builds simplify relocation, owners should still confirm local zoning and Development Application (DA) requirements before installation. Most rural councils classify portable or demountable stables as temporary structures, but they may still require storm rating certification, distance offsets, or flood zone documentation.

ROI & Property Value: When Quality Becomes Equity

When property layouts change, panels don’t become waste; they become assets. Each section can be reused, resold, or refitted into a new configuration. It’s circular construction in its simplest form: buy once, use well, and keep it working.

Modular and movable buildings can increase the value of a property by 5–10%, especially in places where local rules or risks of flooding and fire limit permanent structures. Each Guerilla Steel panel is both a working structure and a resale-ready asset, giving owners flexibility that fixed barns can’t match.

And the return isn’t just at sale. While cheaper imported frames may look 15% less upfront, they typically require connector or infill replacements within five years, wiping out any savings. Over a 25-year service life, those recurring repairs can double the total cost of ownership.

Flood- & fire resistant

In rural Australia, weather isn’t just unpredictable; it’s unforgiving. Floods can swallow entire structures; fire can turn fixed barns into write-offs overnight. Recovery often means starting from scratch.

Guerilla Steel builds resilience from panel to full stability. Our prefabricated panels can be dismantled and cleared before major weather hits, then reinstalled once it’s safe. It’s practical disaster insurance, built into your infrastructure, not added after the fact.

Site Adaptation: Ready for Any Ground You’re On

Guerilla Steel panels are manufactured to perform in real rural conditions, not just on perfect concrete slabs. Each panel is manufactured with a built-in levelling tolerance, enabling secure alignment across grass, gravel, compacted soil, or slab foundations while maintaining structural geometry and load accuracy.

Structural anchoring is achieved through base plates compatible with slab-, purlin-, or post-mounted substrates, providing resistance to lateral and uplift loads encountered in open or high-traffic areas.

Each base connection is also configured to integrate with drainage and flooring gradients, typically a 1–2% surface fall beneath rubber matting or flooring interfaces, preventing fluid pooling and protecting material performance under repeated wet-dry cycles.

This adaptability allows the same configuration to start on natural ground today and transition seamlessly to a slab foundation later, without modification or rework.

For site-specific conditions, floodplain installations, or future expansion layouts, our Prefabricated Extensions and Stable Site Preparation guide are both developed to ensure the foundation supports the structure for the long run.

Have more questions about our prefab panels ?

Can I start with one stable and add more or change the layout later?

Absolutely, that’s one of the biggest advantages of modern modular steel stable systems. Each stable bay is designed as part of a bolt-together framework, meaning you can start small and expand over time without needing to rebuild from scratch.

Modular kits expand easily bay-by-bay, just unbolt the end wall and add matching panels. Learn more about our Prefabricated Panels here or view panel pricing.

When you’re ready to grow, simply unbolt the end wall of your existing stable and attach new prefabricated panels and roof sections. The interlocking frame ensures perfect alignment, maintaining full structural integrity and appearance. Expansion can include extra stalls, tack rooms, feed bays, or wash-down areas, depending on your site layout and future needs.

Because all panels are factory standardised, a bay purchased today will seamlessly fit with extensions you add years later, no custom engineering or re-drilling required. Most owners in regional areas expand in 1–2 bay stages, using the same foundations and roofing style for a clean, professional finish.

You can learn more about Guerilla Steel’s Prefabricated Panels & Pricing here

Will prefab panels fit my current shed or barn?

Most likely. We can prefabricate to match almost any structure.

How long does it take to setup a Guerilla Steel Stable kit?

A 1 or 2 bay setup can be installed in a day by two people. Larger multi-bay stables may take a weekend. Our flat-pack kits come pre-welded and labelled for a no-fuss build, and every part is designed to align correctly the first time.

What materials are Guerilla Steel stables made from?

The materials used are Australian steel – galvanised and prefabricated in our Yatala workshop. The Stable Frames are RHS 50mm Steel tube and 4mm gal mesh on gates and upper panel sections. Ply inserts fit the lower panels (or can be custom fit for full ply upper and lower). Roof sheeting is Monoclad – again Aussie Steel and cut to fit. Check out our base model comparison page where you can find detailed specs and options.

Style is important, what if I want a Luxury High spec stable build?

You can have a luxury, high-specification stable with Guerilla Steels Modular System. Our builds don’t just tick the functional boxes (strength, durability, safety); they’re designed for easy upgradable premium finishes, thoughtful layout, and custom aesthetics that match high-end equine facilities.

You don’t have to imagine it, check out this Indoor Horse Stable Retrofit project, we transformed an existing space into a premium indoor stable setup Engineered strength with refined use of space and airflow. Or the 4-Bay Black Breezeway Retrofit is another great example of a high-spec build is this retrofit breezeway with a sleek black exterior that not only looks stunning but enhances usability for horses and handlers alike.