You don’t want to outgrow your first stable without options for down the road. Your herd expands, you want to open up a new paddock or maybe your training setup needs to evolve and change , that’s where a prefab design system proves their worth.

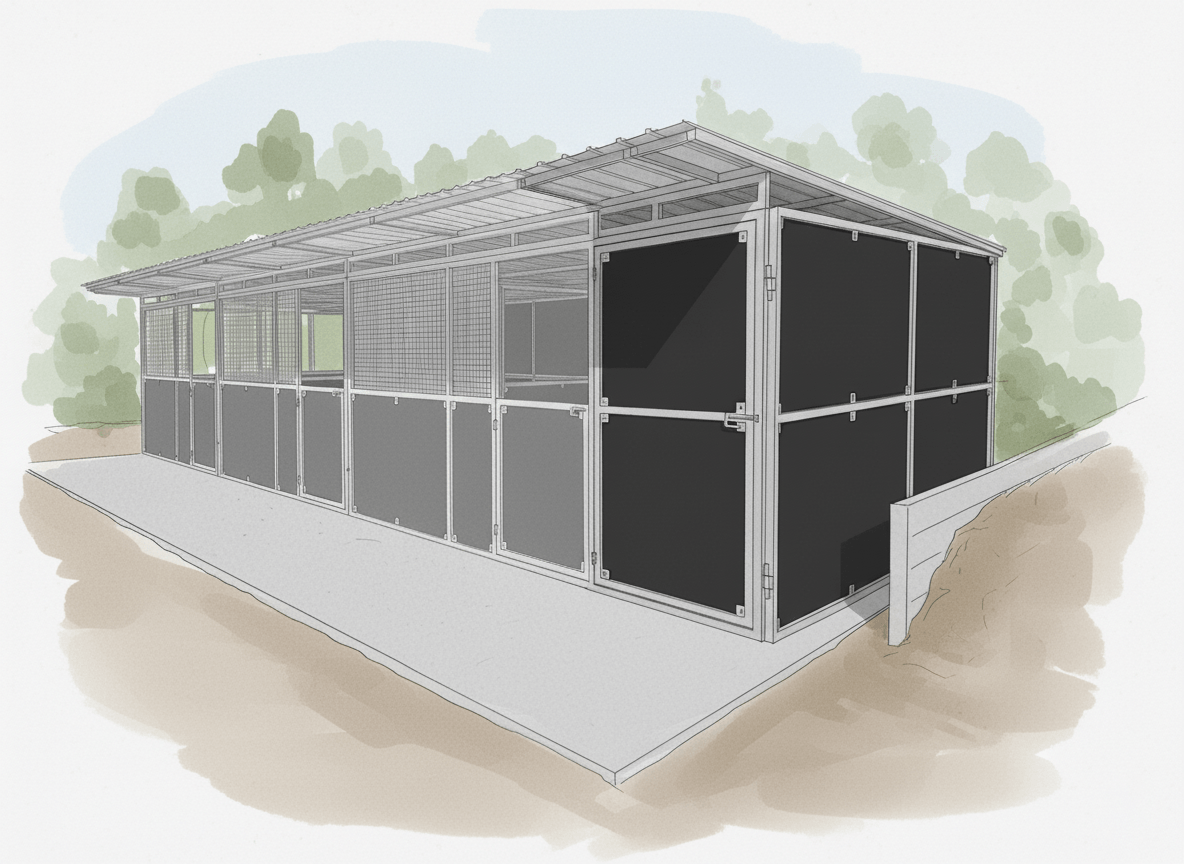

A Guerilla Steel modular stable is a structural system designed to expand or change easily, bay by bay, without starting over. Each panel is prefabricated then delivered flat for transport efficiency. You get a fast setup now, permanent integrity with flexibility for later.

Where a traditional build locks you into a layout, a flexible stable system provides future scale without waste. Add a second bay or a tack room, expand to the side, the rear or even the front – the engineering, alignment, and finish all stay consistent.

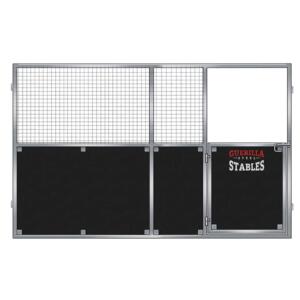

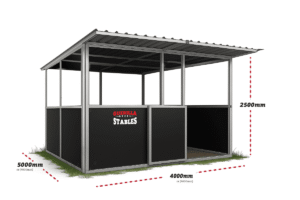

Our retro fit standalone field shelter kits are built as 4m and 5m lengths (side rear or front panels) forming the flexibility of a base shelter for your horses. Each unit arrives complete with roof framing and sheeting, creating a self-contained practical solution from day one.

From there, you can adjust the design to specific requirements. Improve Airflow and comfort through optional upgrades like sloped front roof framing, or ply/mesh panel combinations, mixing materials and orientations built to withstand your regional climate and daily workflow

Front Panel – from $1,050

Side, Rear and Internal Walls – from $950

Build and Expand Modular

Standard 4x4m Base model from $4,500

Together, these form the expansion ready grid that defines every flat pack stable, flexible in design, fixed in quality. Every kit includes the full structural package, welded frames, roof framing, gates, and cladding, with no hidden add-ons for height, overhang, or essential fittings. What you see is what you’ll build.

How Modular Kit stables Work

A kit-based stable build is a precision-engineered frame system, fully welded and galvanised in the workshop, to fit together perfectly on-site.

Each structure is made from welded 50x50mm RHS Australian made quality steel tubing, ensuring accuracy, alignment, and long-term strength, without the need for on-site fabrication and special tools to build.

Every bay begins as a set of wall panels, roof purlins, and hardware packs, numbered and pre-aligned for straightforward assembly. You’re not fabricating; you’re connecting high quality engineered components built to specification.

The process itself is methodical but simple:

- Layout, Position each pre-fabricated frame according to your plan.

- Align, Bolt & Lock, Connect frames easily using the supplied sleeves and fixings.

- Brace, Secure structural rigidity through designated bracing and anchor points.

- Clad & Finish, Add your chosen ply or sheeting to complete the walls.

Because the strength is built into the frame itself, on-site assembly relies more on lining up the parts and securing the connections than on construction skill. Each weld is completed under controlled workshop conditions, so every bay leaves the factory with the same load-bearing strength, kick resistance, and alignment accuracy.

Consistency still depends on getting the on-site bolting, anchoring right and doing regular maintenance. Proper fastening to the slab or shed base, along with galvanising touch-ups at any site-cut points, ensures long-term protection and performance.

Unlike lightweight flat-pack sheds that depend on thin sheet metal for stiffness, these are fully welded RHS high-quality steel modules built for Australian conditions. The frame carries the structural load, not the cladding. Each main stall panel is factory welded into a rigid module that reduces flex at joints and distributes both impact and wind loads evenly through the structure.

When you’re ready to expand, the system is already engineered as an adaptable steel frame. Unbolt the end frame, connect the next bay, and your stable grows without re-engineering or structural compromise. That’s the essence

Field Shelter Scalability: Start Small, Expand Smart

Expansion without disruption is the real advantage – Most horse owners don’t build their dream setup in one go. Herds grow, needs change, and budgets move with the seasons. That’s why a modular stable isn’t just a structure, it’s a growth strategy. Each bay is designed to connect, extend, or convert without pulling anything apart.

Start with a single 4 m or 5 m bay, then expand the line as your horses or operation demand it. Add a second bay over a weekend, or turn an existing stall run into a breezeway and split or convert into tack room later on. Because every frame uses the same Australian RHS galvanised steel, every new addition aligns perfectly with the original build, same roof height, same structural rhythm, same finish.

The pre-fabricated interlocking system maintains full structural strength when a new bay is added, so you never have to rebuild existing work, just order the next front, rear, and end panel set, add the matching roof section, and continue the line.

Owners commonly stage their growth like this:

- 1 → 2 Bays: weekend install,

- Add Tack or Feed Room: bolt-in panel set with internal wall lining

- Introduce Breezeway or Wash Bay: extend roof framing, link existing runs

Each step keeps your property functional during the upgrade, no shutdown, no mess, and no loss of use.

The same adapt and scale logic applies to layout. Frames can form straight runs, L-shapes, or mirrored rows with a central breezeway. Optional roof slope kits and ply/mesh combinations make it easy to adapt airflow and weather protection as the complex grows.

Real owners prove how effective this staged model can be. One hobby farm near Ipswich began with a two-bay setup, added a third within six months, and converted one bay into a tack room the following year, all without structural changes or wasted material. Another training yard north of Tamworth expanded from four to six bays in under a week by unbolting the end frame and continuing the line.

Costs stay predictable because each new module is a repeat of the first. A typical add-on bay runs $4000-5000, installed in less then a days. By spreading upgrades over time, owners smooth cash flow and maintain professional-grade quality from the first weld to the last bolt.

Sables are built to suit what you need now, expand when you’re ready. The engineering never changes; only the footprint does.

Strategy Check building a horse stable – Modular or Custom?

Answer a few quick questions about your site, budget, and plans below. We’ll help you decide whether a kit system that’s both transport Friendly and ready to assembly on site is the smarter choice for you.

It only takes a minute, and it’ll save you time, money, and second-guessing later.

Please select an option to continue.

Whatever you choose, prioritise welfare and safety standards — like 2.4 m height, strong airflow, and properly engineered footings — across all designs.

Modular horse stables make perfect sense when flexibility, speed, and staged investment matter more than architectural flair. They give you a structure that grows with your horses, not against them. But they’re not for every property or project, and knowing when they don’t fit is just as important as knowing when they do.

Where Modular shelters designed to Shine: Flexible, cost-effective, Faster Setup

| Growing herds or phased budgets | If you plan to expand gradually, a scalable stable solution available as a diy kit is a perfect solution. Start with one or two bays, then add more when you’re ready. Each new bay bolts directly onto the previous one, no redesign, no tear-down, no wasted material. Owners typically save 20, 40% upfront compared with building everything at once. |

| DIY-friendly or local crew projects | You don’t need to be a builder. Each pre-welded panel arrives ready to connect with basic tools, meaning most handy owners or small local crews can have the frame up in a weekend. It’s ideal for rural or regional properties where professional builders are harder to find. |

| Simple, stable sites | If your property already has a flat base, shed, or levelled slab, you’ve likely got a safe and secure environment for an expand-on-demand system. Prefabricated panels bolt straight to a prepared surface or existing structure, no major earthworks or engineering required. |

| Design That Adapts when you need it to. | You can shift panels, add tack or feed rooms, extend breezeways, or upgrade airflow and shading as your property or equestrian discipline changes. No starting over. No wasted investment. Just a design that grows with your horses, season by season. |

Building Custom Horse Stables – Complex Sites and Premium Finishes

| Complex or difficult terrain | If your site is sloped, flood-prone, or in a high-wind or bushfire zone, you’ll likely need engineered footings and bracing beyond what a DIY flat pack or standard stable offers. A full custom build will handle those challenges better. |

| Large or urgent full-facility builds | If you need a six-bay complex, wash bays, and tack rooms operational next month, phasing the project in modules can actually slow you down. Custom fabrication or turnkey builds may suit those timelines better. |

| Architectural or aesthetic priorities | Curved façades, integrated arenas, and designer finishes often exceed what a modular frame can achieve. Those belong in a bespoke design project, not a kit-based structure. |

| Limited labour or time for assembly | While DIY builds save money, they still need someone capable flat pack frame assembly. If you don’t have that help nearby, a professional installation is a necessary cost that can be offset by savings from a kit-form stable build. |

Flat Pack field shelters Delivery & DIY Kit Installation

Fast delivery and simple setup are at the core of the modular system. Each kit is engineered for transport efficiency, which means less freight cost, easier handling, and faster builds once on site.

The new 2.4 m standard height makes delivery smoother across regional routes, tall enough for proper airflow, but compact enough to fit standard freight dimensions. Every panel is pre-welded and pre-labelled before leaving our Queensland workshop, so it arrives ready to go.

For most owners, assembly takes a weekend or two(for larger setups) with a small crew and basic tools. You’ll unpack, align, and bolt the main frames into place, then secure roof sheets and internal fittings. Because the weld work is already complete, on-site time is spent aligning and fastening, not measuring or cutting.

Prefer a hands-off build? Professional installation can be arranged by a local team that can handle complete setups for properties across Queensland and northern New South Wales. They take care of site levelling, anchoring, and alignment so you get a ready-to-use stable without lifting a spanner.

If you’re comparing DIY vs. professional builds, our detailed guide breaks down both paths, from timelines to labour expectations and cost differences. Read more: DIY or Builder, Which Stable Installation Is Right for You?

Modular Stables are the “Build Smart, Spend Smarter Option

Building or upgrading stables isn’t a spur-of-the-moment decision. It’s a serious investment one that balances care, safety, and long-term value. For most equine enthusiasts, the real challenge isn’t whether to build, but how to do it in a way that makes sense now and still works years down the track.

A functional stable system with expansion capability, is not about cutting corners or chasing the lowest quote. They’re about spending smarter over time, starting with a strong, permanent foundation and expanding as your herd or property grows. Instead of committing all your capital upfront, you invest in a framework that’s ready to grow with you.

You get a functioning stable now, and the option to scale later, without structural waste or redesign. Start with a one or 2-bay starter kit from around $5,000 to $9,000 then add-on bay later: $4,000+ each This staggered approach smooths cash flow, lets you plan upgrades around seasons or horse additions, and avoids the financial pressure of a single, high-cost project.

The ROI is more than just cost management, it’s flexibility. Because each new bay connects to the last, you’re never rebuilding or wasting previous investment. Every dollar spent on the first setup becomes part of the final structure.

Long term, the 50×50 mm RHS galvanised panelling resist movement, rust & corrosion, and impact, meaning less maintenance and virtually no replacement cost. When reselling, modular systems retain real asset value, they can be reconfigured, or relocated as portable horse stables.

It’s a simple equation: build smaller now, grow smarter later, and every stage of investment works toward your long-term infrastructure, not against it.

How Real Owners Expand Their Modular DIY Stables

The modular system is built around adaptability. Whether you’re expanding an existing run of stables or repurposing a shed, each new stage connects to the last without structural change or wasted material. Here’s how the most common upgrades play out in practice.

Expanding from One Bay to Two, The Quickest Upgrade

For many owners, the first expansion happens fast, usually when a second horse arrives or storage space runs short. A standard 4 m bay connects directly to the end of the first with matching front, rear, and end panels plus a shared roof section. The process typically takes a weekend with two people and basic tools. Cost-wise, a second bay adds around $4 000, depending on cladding and roof finish. The welded joints maintain full structural strength, so there’s no rebuild or re-engineering, just bolt, align, and secure.

Adding Tack or Feed Rooms, Smarter Workflow, Same Structure

Once you’ve got two or three bays, workflow becomes the next focus. A tack or feed room can be added as a bolt-in module using solid ply lower panels for storage and mesh uppers for airflow. Many owners add these near a breezeway or end wall to improve access. Typical install time: 1, 2 days. Because each room shares the same frame format, it integrates seamlessly with existing walls and roofing, no uneven join lines or mismatched materials.

Retrofitting an Existing Shed, Make the Most of What You’ve Got

If you already have a shed or barn structure, converting it can be far more economical than a ground-up build. Modular internal fit-outs use the same prefabricated stall frames and gates as freestanding stables but bolt directly inside the existing shell. Most installs take two to three days, require no structural cutting, and preserve the shed’s integrity.

You can read a full breakdown in our guide: Shed to Stable Retrofits, How to Convert Existing Structures into Safe Horse Stables

Need Help Choosing? Message Us!

Contact us today to start planning a stable that keeps your horses safe and calm and saves money where it counts.

Build smart, Build Bigger and Build Stronger with Guerilla Steel

Modular Growth in Action: Real horse owner projects, Real Results

Each project shows the future-proof stable promise: build once, expand when you want, and maintain full control at every stage. Our Customer results share one theme: strength, speed, and smart design. Here are a few real-world builds that show how panel-based framework scalability works day-to-day.

Logan Village 3-Bay Horse Stable with Tack Room

Size: 14.5 m × 4 m (58 m²)

A clean, functional layout that handles daily use, future expansion, and Queensland weather without a single compromise. Built for a working property that needed flexibility, this premium three-bay stable integrates a secure tack room with solid ply walls, mesh tops, and full-span weather-proof roofing. It’s taller and tougher than the standard frame, because this owner wanted space to move and the additional airflow.

Beaudesert, Two-Bay Shed Retrofit to horse shelter

Size: 8m × 5 m (40 m²)

When Jodie’s mare needed a calm recovery space, a modular retro fit was the smartest move. Anchored directly into the existing concrete, the setup respected the original structure and kept the project fast, clean, and cost-controlled .In just one day, the install team transformed the shed into a quiet, weather-tight shelter that still leaves room for future expansion.

Samford Valley, 4 Stall Modular Panel Systems in Action

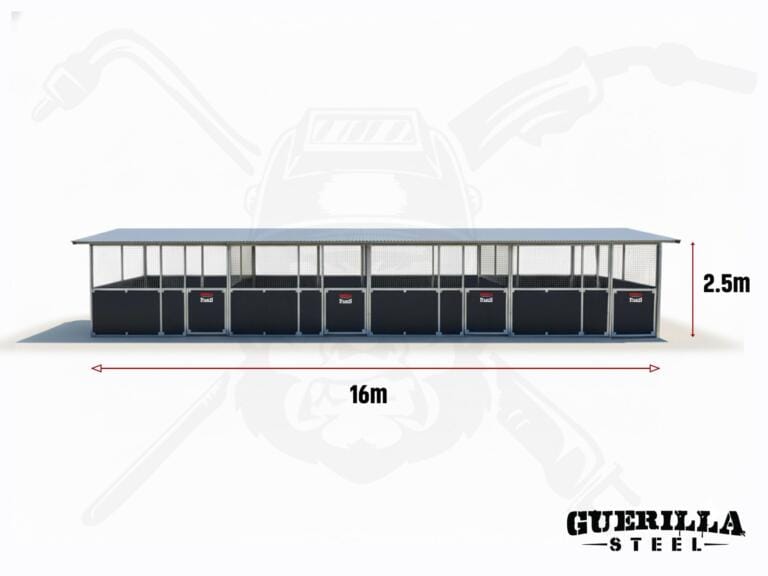

Size: 16 m × 4 m (64 m²)

The 4-bay modular stable built in Samford Valley, QLD shows exactly how our panel-based design performs in real conditions.

Each 4 × 4 m bay uses Australian steel frames, solid ply kickboards, and mesh airflow panels—the same core system supplied in our flat-pack stable kits. Delivered pre-welded and precision-aligned, these panels lock together on site to form a clean, scalable 16-metre line that can grow to six or eight bays without rework.