It’s easy to see a low price and think you’ve found a bargain. But with stables, what looks like a saving can turn into months of repairs, wasted weekends, and costly vet visits.

Here’s what really happens when the “budget kit” arrives, and how to calculate the true cost before you buy.

Flimsy Frames: The Repair Bill You Didn’t Budget For

Every stable copes with daily force, kicks, rubs, and the constant pressure of a thousand movements.

Cheap imported kits aren’t built for that reality. They use light-gauge steel joined with thin bolts. Those connections become the weak link: they rust, flex, and eventually fail.

The Engineering Difference: Bolted Panels vs Bolted Frames

Here’s where most buyers get misled.

- A bolted frame kit connects entire wall panels together, edge to edge, and locks corners so the load transfers through the full structure.

- A bolted panel (what most cheap imports are) joins smaller sheet sections with single bolts every few hundred millimetres.

Each join interrupts the load path, meaning every kick or rub concentrates stress on those bolt holes instead of distributing it through the frame. Over time, holes elongate, joints loosen, and the whole structure begins to rattle.

The Cost That Follows Bolted Panels

Once those joints start moving, corrosion creeps in.

You’ll spend weekends re-tightening, replacing bolts, and chasing leaks that never stay fixed.

It’s not just time lost, it’s labour cost, fasteners, and the slow fatigue of watching a “new” stable deteriorate year by year.

Prefab Stable Panels – That bolt, lock and hold

A fully welded 50 × 50 mm RHS galvanised frame eliminates those weak points.

Load travels continuously through the welds, not bolts.

There’s nothing to loosen, nothing to rust at the joints, and no mid-season patch jobs.

You pay a little more once, and you don’t pay again for decades.

The Structural Short-Cut Trap

After frame design, the next structural shortcut often hides in the material itself. If the structure must handle years of kicks, rubs, and Queensland summers, it’s not a plastic problem, it’s a physics problem. Only rigid steel frames solve it. Not every “steel-look” frame is truly engineered steel, and not every alternative is wrong, provided you understand what it’s built to do.

Common Materials in Cheap Stable Kits

Many low-cost stables replace welded RHS galvanised steel with lighter substitutes. These include:

- HDPE plastic composites or recycled plastic lumber, used for walls, boards, and sometimes framing. They resist moisture and rot, but flex under impact.

- PVC or polyethylene panels, light, modular, and easy to assemble, but prone to cracking in cold or high-UV conditions.

On paper, these materials promise durability with low maintenance.

In practice, they trade structural rigidity for convenience and price.

The Structural Reality: Plastic-based frames behave very differently under force.

When a horse kicks a wall, the impact transfers through the entire structure. Steel dissipates that energy through its welds and rigid geometry. Plastics and lightweight alloys absorb it by flexing, and every flex weakens the fastenings that hold panels together. Over time, you’ll see sagging doors, misaligned bolts, and the subtle warp that makes a stable feel “off square.”

In Australia’s climate, UV exposure and temperature swings accelerate that fatigue.

Even UV-stabilised composites lose rigidity after a few years of expansion and contraction cycles.

When lighter materials might make sense.

If you’re setting up a short-term field shelter, miniature horse bay, or temporary agistment setup where relocation is expected, lightweight HDPE or PVC kits can be practical. They’re quick to assemble, easy to move, and fine for mild weather regions where horses spend most time outdoors.

But for any permanent structure, high-traffic stable, or breeding and performance operation, you need welded galvanised steel. It’s the only frame material that remains dimensionally stable under constant impact, humidity, and temperature variation.

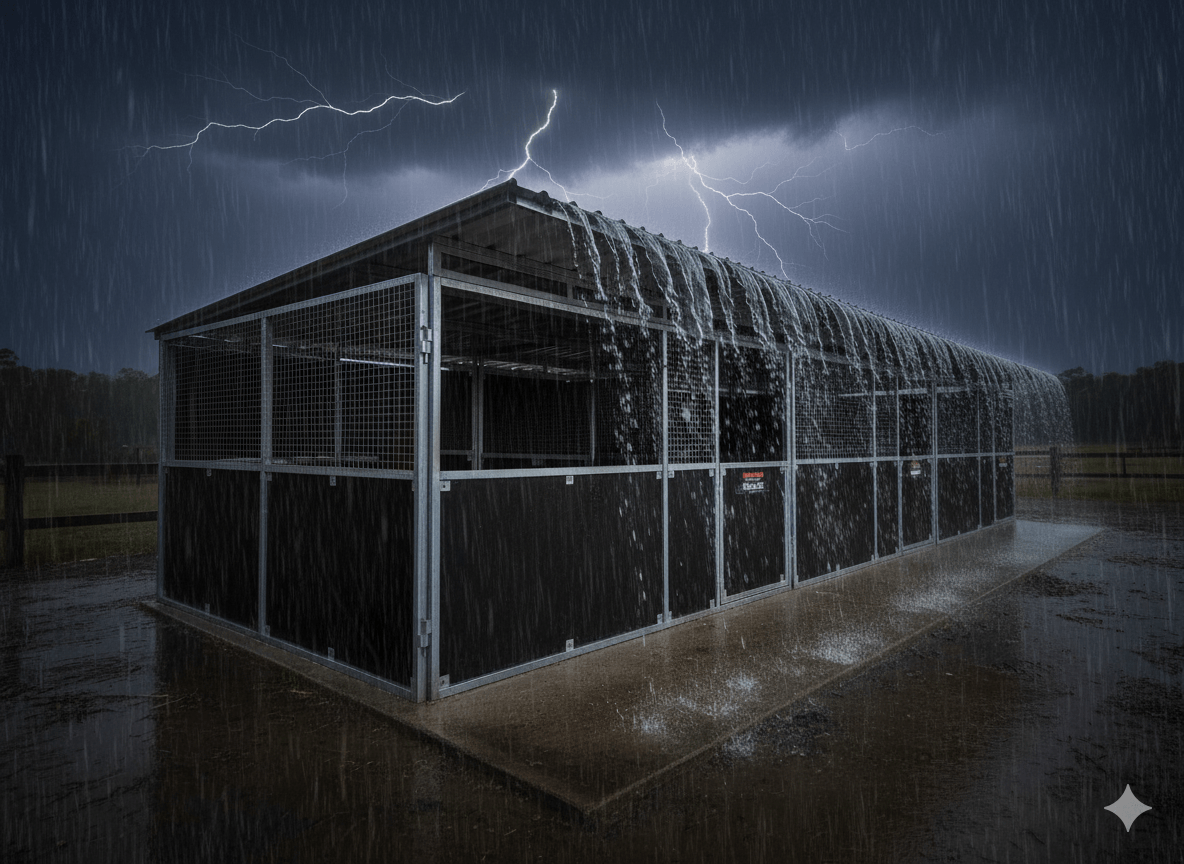

Weather-Proofing Corners That Don’t Exist

Low-priced designs often delete or use minimal roof overhangs. Without that 900 mm front cover or compacted base, rain drives straight into the bay, creating mud, rot, and footing hazards.

Re-levelling and drainage fixes later can double the original spend.

Factor in weather, wind direction, local rainfall and site slope before finalising your order. A well-planned pad costs less than post-install repairs.

The Hidden Labour Bill: When “Self-Assembly” Becomes Self-Repair

Imported self-assembly kits look like savings on paper, until the first weekend you spend tightening bolts that won’t stay tight.

Flat-packs made overseas aren’t built for Australian tolerances or weather. By the time they arrive, the panels have twisted in transport, holes don’t align, and you’re left re-drilling and re-engineering a structure that was meant to be simple.

Imported “Support” is rarely a quick fix.

When things don’t fit, You send an email. Wait. Maybe a replacement part arrives six weeks later, or maybe it doesn’t. Return shipping costs more than the component itself. And you end up paying twice: once for the kit, and again for the frustration.

The Local Difference, you’re not just buying a stable, you’re buying a relationship.

Our workshop is right here in Yatala, between Brisbane and the Gold Coast. You can walk in, see the steel being welded, and talk to the same people who’ll build your frames.

If something ever needs adjustment or advice, you’re dealing with locals who know your climate, your soil, and your standards, not an offshore call centre.

Get the “Questions to Ask your stable builder” guide

412 downloads this month ⭐ 5 avg rating from buyers | Last download 4 hours ago

Built for Your Next Chapter, Not Just This One

We want you to be happy with your first stable, because most of our customers expand later.

When you’re ready to add more bays or retrofit an existing barn, we already know your design and can build matching modules in weeks, not months.

That’s the difference between imported convenience and Australian-made continuity. You’re not buying a box of parts. You’re investing in a team that’s close enough to shake your hand, and still around when you’re ready to grow.

Heat, Height & Horse Health

A stable isn’t a shed. Horses generate humidity and heat, and without proper roof height and airflow, that heat stays trapped.

Cheap kits often drop ceiling height below 2.5 m to cut material costs. The result? Hot, stagnant air that leads to dehydration and respiratory stress.

The welfare math:

Vet visits for heat stress or coughs cost far more than the steel you saved.

A 2.5 m minimum height isn’t a luxury, it’s the ventilation standard that keeps horses healthy.

When Retrofitting Saves More Than Rebuilding

Sometimes the smartest budget move isn’t a new structure at all. Retrofitting a quality steel panel system into an existing shed keeps foundations, roof, and approvals intact, cutting costs by up to 40%.

If your site already has solid bones, retrofit economics win every time.

Stable Cost Check – The Long-Game Equation

Think in decades, not months. Buying cheap isn’t always wrong, it’s just incomplete math.

The right question isn’t “What’s the lowest quote?” but “What will this cost me to own for ten years?”

When you calculate that figure honestly, quality steel stops looking expensive, it looks inevitable.

A welded, Australian-made stable built to welfare and engineering standards might cost 25, 30 % more upfront, but avoids 10, 15 years of cumulative repairs and vet bills.

That’s the real ROI: durability + animal health + time saved.

| Cost Factor | Cheap Kit | Quality Build |

| Initial Outlay | $ Low | $$ Moderate |

| Annual Repairs | $ 1 000 + | $ 200, 300 |

| Vet/Health Risk | High | Low |

| Resale/Relocation | Limited | Strong |

| 10-Year TCO (approx.) | $ 30 k + | $ 22 k, 24 k |

Ready to budget for a stable that lasts a lifetime, not just a few years? Take our Stable Finder Quiz for an instant recommendation or complete our Easy Quote Form.