Horse Stable Building Site Prep, Made Simple

Planning a new horse stable? You’re probably thinking about size, airflow, or tack room options, not dirt. But proper site prep is what makes or breaks a good, stable build. It’s not just about pouring concrete or levelling dirt. It’s about getting a safe, dry, and solid foundation so your horses, gear, and structure stay protected for years.

Here’s a straight-talking guide to getting your site ready with practical advice that saves you time and money.

Why Proper Stable Site Prep Matters

We’ve seen it too often, especially with DIY builds and low-quality import stables, that have been slapped on soft or uneven ground. Six months later, the doors don’t shut properly, water’s pooling inside, and the whole structure starts shifting.

Here’s what good prep actually does:

- Keeps your stable level and secure

- Prevents drainage headaches and boggy floors

- Makes delivery and install faster

- Helps your stable last longer

It’s 30% of the job, but it solves 90% of future problems.

Step-by-Step Site Prep Process

Step 1: Pick the Right Spot

Choose a spot that’s:

- Easy to access by delivery truck or trailer

- Not in the lowest part of your paddock or flood-prone

- Clear of overhanging trees, roots, or large rocks

- Facing away from harsh winds (if possible)

💡Tip: Allow for at least 1m clearance around the stable, especially under the 900mm roof overhang we include as standard.

Step 2: Mark Out the Area

You’re not just marking the stable footprint, you’re also planning for:

- Walkways

- Feed room/tack room add-ons

- Yard access or future upgrades

A 4x4m stable with overhang needs at least a 6x6m cleared pad to allow for build space.

Step 3: Clear and Level

Every property is different and not every stable needs to go on a hard base. We’ve installed units straight onto flat grassed paddocks where owners wanted a more temporary or flexible solution.

That said, for most builds, we recommend a firm, compacted base. It keeps the structure stable, prevents movement over time, and makes drainage easier to manage.

If going the full prep route:

- Strip off topsoil, grass, and organics

- Remove roots, debris, and soft fill

- Level and compact using road base, gravel, or crusher dust

If installing directly on grass:

- Make sure it’s level, firm, and not waterlogged

- Avoid low-lying or flood-prone areas

- Expect some natural settling over time

💡Tip: Even on grass, adding a gravel border around the edges can help keep mud down and improve drainage.

Step 4: Choose Your Base

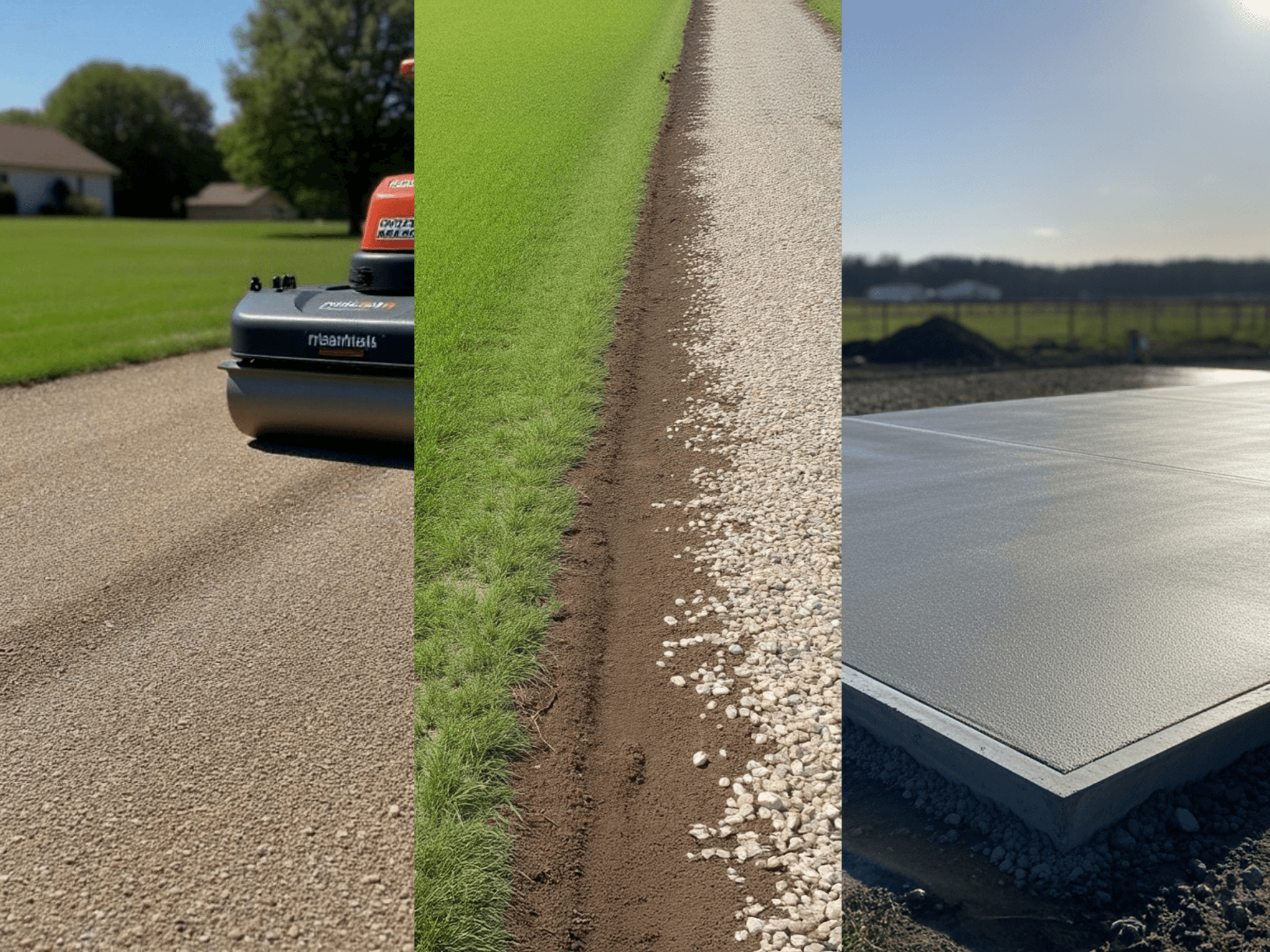

Most Guerilla Steel stables go on compacted road base. But we also build on:

- Concrete slabs – for high traffic, wash bays, or where you want a super-clean floor

- Raised gravel pads – for wet or flood-prone zones

- Grass – fine for lighter use, provided it’s firm, level and not prone to bogging.

- Existing flat concrete – if you already have a strong slab, we can build straight on it.

In the Beaudesert Multi Stable Project we finished last month, we installed on road base. This choice saved the client thousands compared with concrete, and it’s still solid as a rock.

Drainage – The Silent Workhorse

Stable site prep isn’t just about flat land. It’s about where the water goes.

Slope your pad slightly, 1–2% to allow rain to run off.

If you’re on a slope, consider:

- French drains around the site

- A retaining edge with ag pipe

- Extra gravel layers to protect footing

⚠️Warning: Don’t build in a natural basin. Even a well-compacted pad can’t fight gravity in a downpour.

Plan for Power, Water & Access

Don’t forget to plan access before install. Consider:

- Water pipes or tanks for drinking/wash bay

- Power conduit for lights or electric fencing

- Trenches that need to go under the pad

- Where you’ll store gear or feed

If you’re adding a tack room later, make sure you leave the space now.

Weather and Timing

Best time for site prep? Dry season.

Here’s why:

- Wet soil doesn’t compact properly

- Machines can churn up clay into a mess

- Rain delays everything, including delivery

Once your base is compacted, we recommend 2–4 days of dry weather before we roll in with your stable build.

Real-World Example: Modular 4-Bay in Toowoomba

In July 2025, we delivered a 4-bay modular system (4x5m each) for a mixed animal setup, horses, alpacas, and goats. The client opted for a compacted road base with slight slope for drainage. Total site prep cost: $1,800. The install took two days. The stable? Still standing solid and dry months later.

Conclusion: Do It Right the First Time

If you’re going to invest in a high-quality steel stable, don’t cut corners with the ground beneath it. Do it once. Do it properly. Your horses, your structure, and your wallet will thank you later.

Not sure if your site’s ready?

We’ve put together a practical checklist that covers everything from picking the right spot to planning for delivery day

Privacy Policy.